From Sheep to Yarn: The Art of Skirting Wool Fleeces

Over the past few days, I’ve been knee-deep in one of the most important (and often overlooked) steps in the sheep-to-yarn process: skirting fleeces. I’ll be honest, it’s a job I tend to put off, but once I get started, I actually enjoy it. Skirting a fleece means carefully going through it to pull out debris, hay, manure, and other vegetable matter. Each fleece truly tells the story of the sheep that wore it all year, from health to habits. Some fleeces are full of hay and burrs from curious sheep who can’t resist rolling in everything. Others show wool breaks, evidence of stress, illness, or even pregnancy. Even the staple length (the length of each lock of wool) reveals how that sheep has been doing.

The process starts by laying the fleece out on a skirting table, a simple frame covered with chicken wire or mesh that allows second cuts and debris to fall through. The first task is removing the outside edges where most of the manure and hay collect, especially around the neck area. Since we shear in early spring, our fleeces are usually loaded with winter hay, though I often think they’d be much cleaner if we sheared in the fall. As I skirt, I pull out grass, burrs, sticks, and anything else the flock has managed to pick up in the pastures.

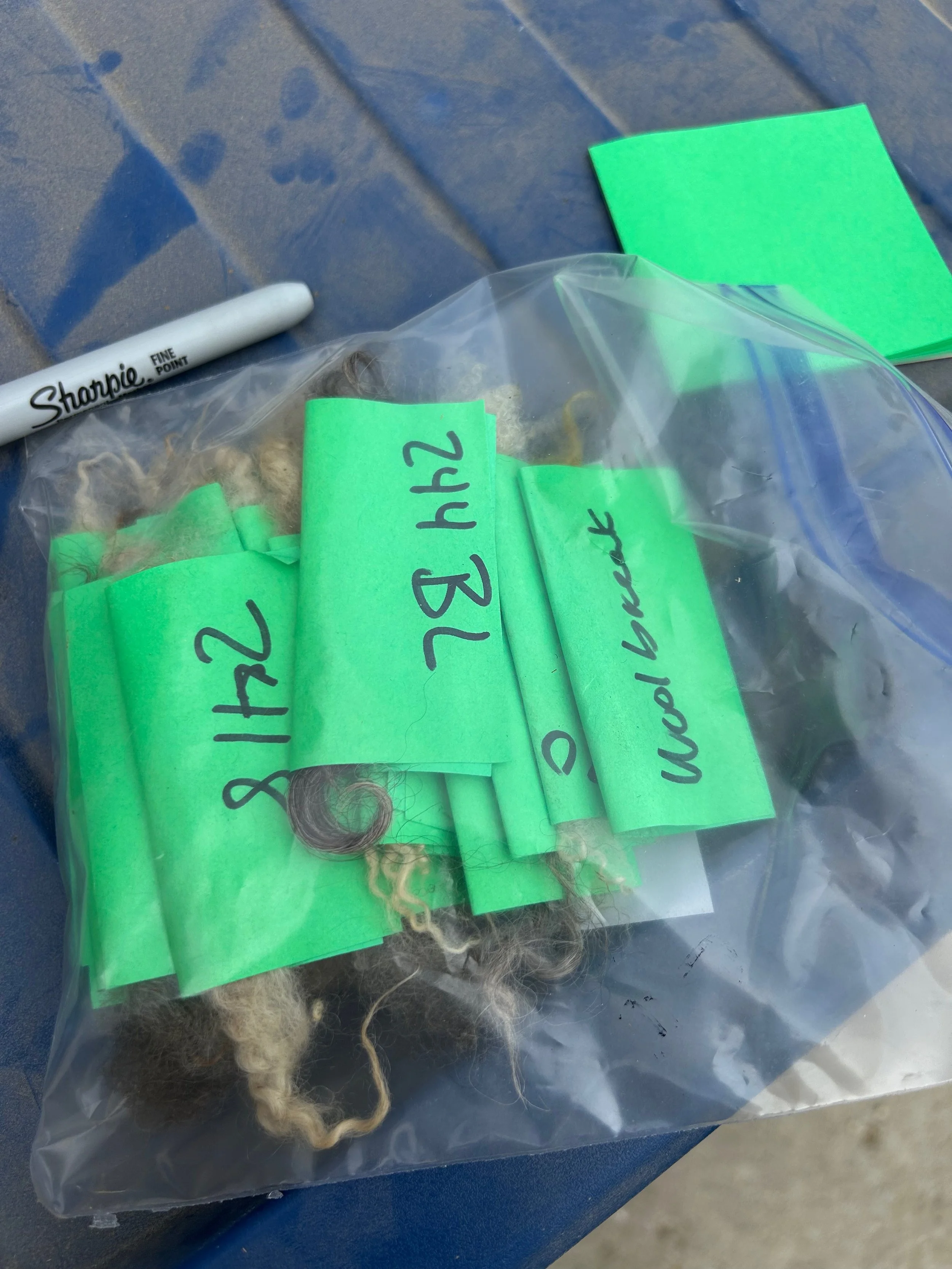

While working, I also take a sample from each fleece. By snapping the wool by my ear, I can check for wool breaks—a healthy fleece gives a satisfying “ping,” while a weaker one will crackle and break. Each sample is labeled, stored, and saved as part of our flock’s record. It’s fascinating to look back at these samples over the years and see how the sheep and their fleeces have changed.

Once skirted, the fleeces are bagged, labeled with the sheep’s number, and marked for how I’d like them processed. Then it’s time for their trip to the fiber mill here in Kansas. This part requires patience; sometimes it takes nearly two years from shearing to finished yarn. But when that box of processed Finnsheep roving and yarn finally arrives, it’s worth every bit of the wait.

Skirting wool may be slow work, but it connects me to my flock in such a meaningful way. From feeding, except on the coldest mornings when it is well below freezing - I hate those days, to finally crocheting with the soft yarn months later, I love every step of the journey. This is what makes raising sheep and producing natural, ranch-raised fiber so rewarding.

Be sure to check out our store if you need any Finnsheep yarn or roving!